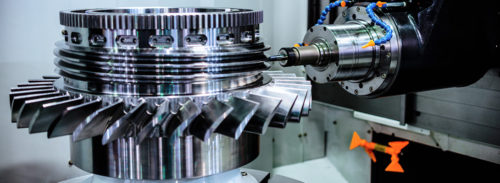

Machining Services

TRS is primarily involved in the specialty type of repairs on Steam, Gas and Hyrdo turbines. Our customers are in the power generation industry and include the major utlities as well as the cogeneration, geothermal and independent power producers. We also service industrial, petrochemical and municipal sectors. These repairs consist of on site machining of turbine components i.e. rotor shafts, seals and other components, which generally require extremely, close tolerances and extra fine finishes.

Mechanical Services

TRS Mechanical group can help you with a variety of services. We provide responsive and timely turn-key equipment disassembly, turn key, inspection, repair, and reassembly. Our expert services can save costs and downtime by ensuring system reliability and availability through the reduction of forced outages and reduced maintenance costs. The same talent and expertise that has been the cornerstone of our success can also be delivered to your facility to provide “First class” solutions.

Electrical Services

Our trained and qualified, Electricians, Instrument, and Test Technicians can provide you with turnkey solution services in all aspects of plant and equipment performance improvements, problem diagnosis, performance measurement as well as installations, modernization, and system upgrades. Our services are utilized by electric utilities, power generators, petrochems, municipalities, and industrials. Our engineers and technicians have extensive experience to improve the reliability and productivity of your facility.

Welding Services

The TRS weld group can provide you with help and assistance to a variety of your plant needs. TRS possesses an “R” stamp for pressure vessels and high pressure steam systems. Our welding group specializes in power generation plants mechanical, steam, boiler, ancillary systems, and other specialized weld repairs.

Boilers Valves Services

Typical boiler or process valve repairs include; field removal of the valve (flanged or welded), incoming inspection and documentation, comparison and verification of OEM tolerances and specifications, field or shop disassembly and inspection. Replacement of worn or damaged components, machining and weld build up of steam cut surfaces and seal areas, and stress relieve when necessary.

Turbine Valves Services

The TRS Turbine valve service group can provide you with help and assistance with a variety of your plant needs. Our turbine valve service group specializes in steam and combined cycles turbine control, stop, throttle, and intercept valves. Valve repairs typically encompass field removal of the valve, shop disassembly and inspection, verification of OEM specifications and tolerances, repair or replacement of stems, gaskets, bolting, replacement or repair of discs, seats, seal areas and caps. Weld repair can include machining of damaged existing stellite, stainless underlay weld build up, pre-machining for stellite overlay, and final machining of stellite repaired surfaces.